Innovative Automation Solutions

Solutions Provided by Sri Sakthi Automation Pvt Ltd

Our dedicated experts ensure efficient project execution, comprehensive maintenance, and top-notch service, reducing costs and minimizing downtime. Contact us for unparalleled support.

Our Principles

Solutions

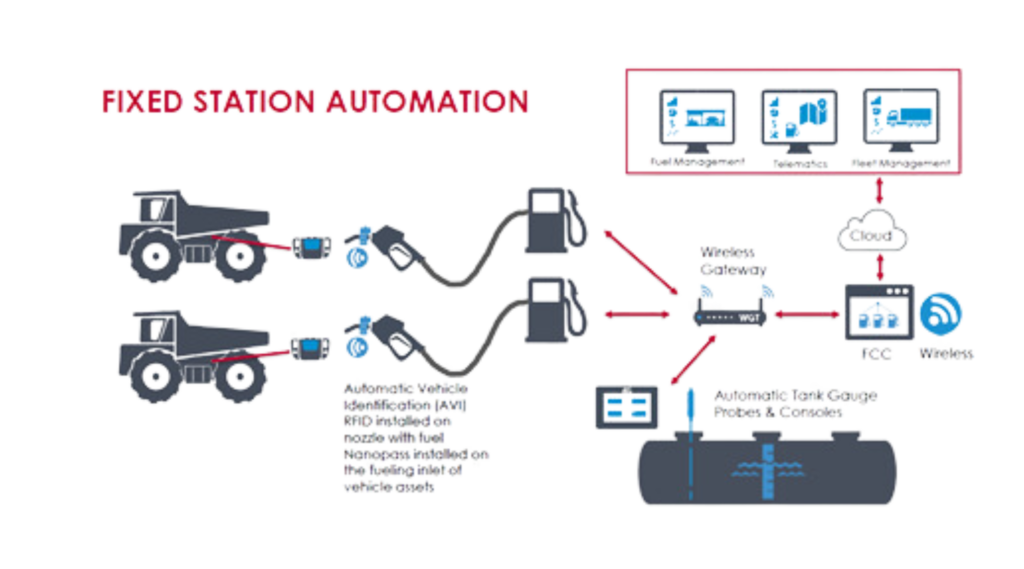

Fixed Station Automation

Fixed station automation is basically a dispenser with an underground storage tank at industrial sites such as mines, crushers, aviation, defense, construction sector, Marine ports and industrial sectors. Each vehicle is equipped with an electronic tag (FuelOpass). It allows comprehensive fuel management through RFID solutions which prevent fuel theft and wastage since when the RFID detects the vehicle, the dispenser starts working. The fuel management can be seen on “Prime360” which is very similar to systems like SAP and cloud.

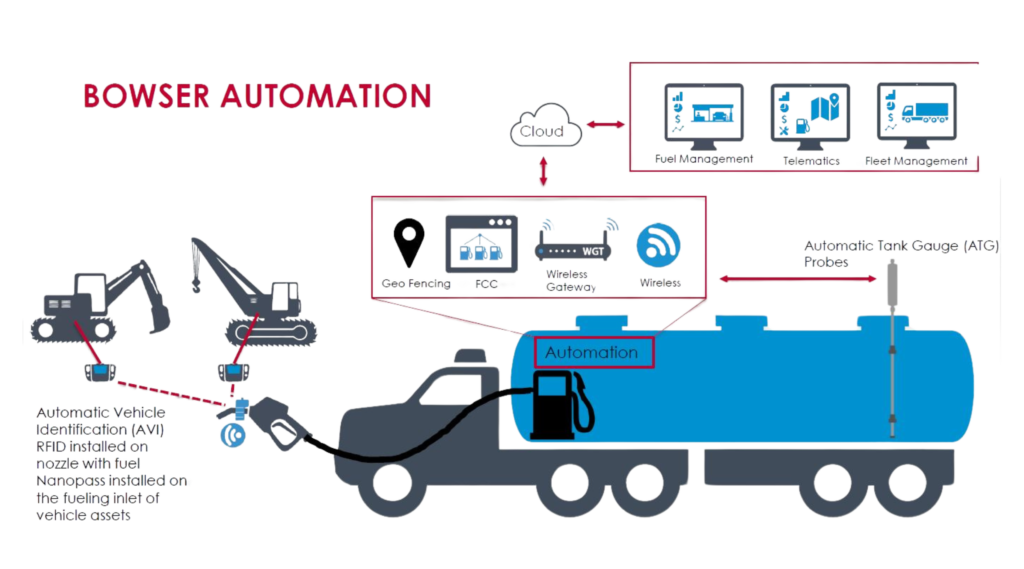

Bowser Automation

The Bowser automation helps to reduce fuel and operational costs, reduce losses and ensures optimal distribution fuel distribution. Bowser automation helps to control the fuel usage while reducing the chance of misuse or losses and it also helps to monitor real-time fuel usage.

Fueling Gantry

A top loading fuel gantry is an on-site system where a separate/dedicated underground tank is used to fuel directly into the top of a mobile bowser. It is faster and safer method of fueling than the manual method with a personnel. This doesn’t block the customer lanes which impleads flow at the site. The gantry comes with PESO approved flow meter system.

Storage tanks

Our fixed station works includes underground storage tanks made of MS/SS depending on customer requirement and properties of medium to be stored, underground tank ranges from 1000 Liters to 90000 Liters and manufactured as per IS / API standards

Fixed station (2KL)

Twin key solutions to meet fueling requirements at construction and mining sites. It includes pre-set and printer facilities where the customer can enter Vehicles number and other details before filling in. It allows the customer install it anywhere cause of the minimal space requirement where the underground tanks and its pipe works requires large amount of space compared to a small fixed station and also the capacity is 2KL.

Consumer pump station

The consumer pump station plays a major role in large manufacturing industries such a cement manufacturing industries, chemical processing industries and also in mining industries which is in a remote areas, it is most ideal way and efficient way of refuelling the mining equipment’s and vehicles. This can be helpful in logistic industries when they need to refuel large number of vehicles at their own yard rather than waiting at a retail station.

Project details and Solutions

Project Client: Dalmia Bharat Cements Limited

Location: Trichy

Duration: 2023-2024

Solutions Provided:

- Fuel Station Automation: Installed two 50KL capacity underground storage tanks equipped with STPs (Submersible Turbine Pumps) for efficient fuel dispensing.

- Dispensing Units: Dual nozzle heavy-duty dispensers with a flow rate of 80LPM each, ensuring rapid and reliable fuel distribution.

- Gantry Setup: Integrated a new Gantry setup with 2’’ EMR4 (Electronic Meter Register) for precise top-loading applications.

- ATG (Automatic Tank Gauge): Installed TLS4B ATG probes for continuous monitoring of fuel levels, water detection, density, and temperature.

- Monitoring System: Implemented an FCC (Fuel Control Center) for centralized monitoring and fleet management, with future plans for a vehicle detection system.

Project Client: NLC India

Location: Neyveli

Duration: 2024 – Present

Solutions Provided:

- Diesel Bowsers: Supplied 7 new diesel bowsers with safety features including fire suppression system, reverse camera, and Fatigue Detection Device as per DGMS regulations.

- Underground Storage Tanks: Provided 11 tanks with 20KL capacity each and installed 25 fuel dispensers (single and dual nozzle) at Mine 1, MINE 1A, and Mine 2.

- ATG (Automatic Tank Gauge): Equipped all underground tanks with ATG probes for continuous monitoring of fuel levels, water detection, density, and temperature.

- Automation Solution: Implemented automation for 1025 vehicles (transportation, heavy vehicles) to track fuel usage.

- Monitoring System: Utilized FCC (Fuel Control Center) for centralized monitoring, telematics, and geo-fencing of heavy machinery and vehicles. Future plans include implementing a vehicle detection system.

Happy Clients

Project, Maintenance, and Service

Our dedicated experts ensure efficient project execution, comprehensive maintenance, and top-notch service, reducing costs and minimizing downtime. Contact us for unparalleled support.